Polyester Enameled Copper Clad Aluminum Wire Class130

| Product Type | PEW/130 |

| General Description | 130Grade Polyester |

| IEC Guideline | IEC60317-3 |

| Temperature Index (°C ) | 130 |

| Solderability | Not weldable |

| NEMA Guideline | NEMA MW 5-C |

| UL-Approval | / |

| Diameters Available | 0.08mm-1.15mm |

| Softening Breakdown Temperature(°C) | 240 |

| Thermal Shock Temperature(°C) | 155 |

| Nominal diameter(mm) | Conductor tolerance(mm) | G1 | G2 | Minimum breakdown voltage(V) | Minimum elongation (%) |

||

| Minimum film thickness | Complete Maximum outer diameter(mm) | Minimum film thickness | Complete Maximum outer diameter(mm) | G1 | |||

| 0.1 | 0.003 | 0.005 | 0.115 | 0.009 | 0.124 | 1200 | 11 |

| 0.12 | 0.003 | 0.006 | 0.137 | 0.01 | 0.146 | 1600 | 11 |

| 0.15 | 0.003 | 0.0065 | 0.17 | 0.0115 | 0.181 | 1800 | 15 |

| 0.17 | 0.003 | 0.007 | 0.193 | 0.0125 | 0.204 | 1800 | 15 |

| 0.19 | 0.003 | 0.008 | 0.215 | 0.0135 | 0.227 | 1900 | 15 |

| 0.2 | 0.003 | 0.008 | 0.225 | 0.0135 | 0.238 | 2000 | 15 |

| 0.21 | 0.003 | 0.008 | 0.237 | 0.014 | 0.25 | 2000 | 15 |

| 0.23 | 0.003 | 0.009 | 0.257 | 0.016 | 0.271 | 2100 | 15 |

| 0.25 | 0.004 | 0.009 | 0.28 | 0.016 | 0.296 | 2300 | 15 |

| 0.27 | 0.004 | 0.009 | 0.3 | 0.0165 | 0.318 | 2300 | 15 |

| 0.28 | 0.004 | 0.009 | 0.31 | 0.0165 | 0.328 | 2400 | 15 |

| 0.3 | 0.004 | 0.01 | 0.332 | 0.0175 | 0.35 | 2400 | 16 |

| 0.32 | 0.004 | 0.01 | 0.355 | 0.0185 | 0.371 | 2400 | 16 |

| 0.33 | 0.004 | 0.01 | 0.365 | 0.019 | 0.381 | 2500 | 16 |

| 0.35 | 0.004 | 0.01 | 0.385 | 0.019 | 0.401 | 2600 | 16 |

| 0.37 | 0.004 | 0.011 | 0.407 | 0.02 | 0.425 | 2600 | 17 |

| 0.38 | 0.004 | 0.011 | 0.417 | 0.02 | 0.435 | 2700 | 17 |

| 0.4 | 0.005 | 0.0115 | 0.437 | 0.02 | 0.455 | 2800 | 17 |

| 0.45 | 0.005 | 0.0115 | 0.488 | 0.021 | 0.507 | 2800 | 17 |

| 0.5 | 0.005 | 0.0125 | 0.54 | 0.0225 | 0.559 | 3000 | 19 |

| 0.55 | 0.005 | 0.0125 | 0.59 | 0.0235 | 0.617 | 3000 | 19 |

| 0.57 | 0.005 | 0.013 | 0.61 | 0.024 | 0.637 | 3000 | 19 |

| 0.6 | 0.006 | 0.0135 | 0.642 | 0.025 | 0.669 | 3100 | 20 |

| 0.65 | 0.006 | 0.014 | 0.692 | 0.0265 | 0.723 | 3100 | 20 |

| 0.7 | 0.007 | 0.015 | 0.745 | 0.0265 | 0.775 | 3100 | 20 |

| 0.75 | 0.007 | 0.015 | 0.796 | 0.028 | 0.829 | 3100 | 20 |

| 0.8 | 0.008 | 0.015 | 0.849 | 0.03 | 0.881 | 3200 | 20 |

| 0.85 | 0.008 | 0.016 | 0.902 | 0.03 | 0.933 | 3200 | 20 |

| 0.9 | 0.009 | 0.016 | 0.954 | 0.03 | 0.985 | 3300 | 20 |

| 0.95 | 0.009 | 0.017 | 1.006 | 0.0315 | 1.037 | 3400 | 20 |

| 1 | 0.01 | 0.0175 | 1.06 | 0.0315 | 1.094 | 3500 | 20 |

| 1.05 | 0.01 | 0.0175 | 1.111 | 0.032 | 1.145 | 3500 | 20 |

| 1.1 | 0.01 | 0.0175 | 1.162 | 0.0325 | 1.196 | 3500 | 20 |

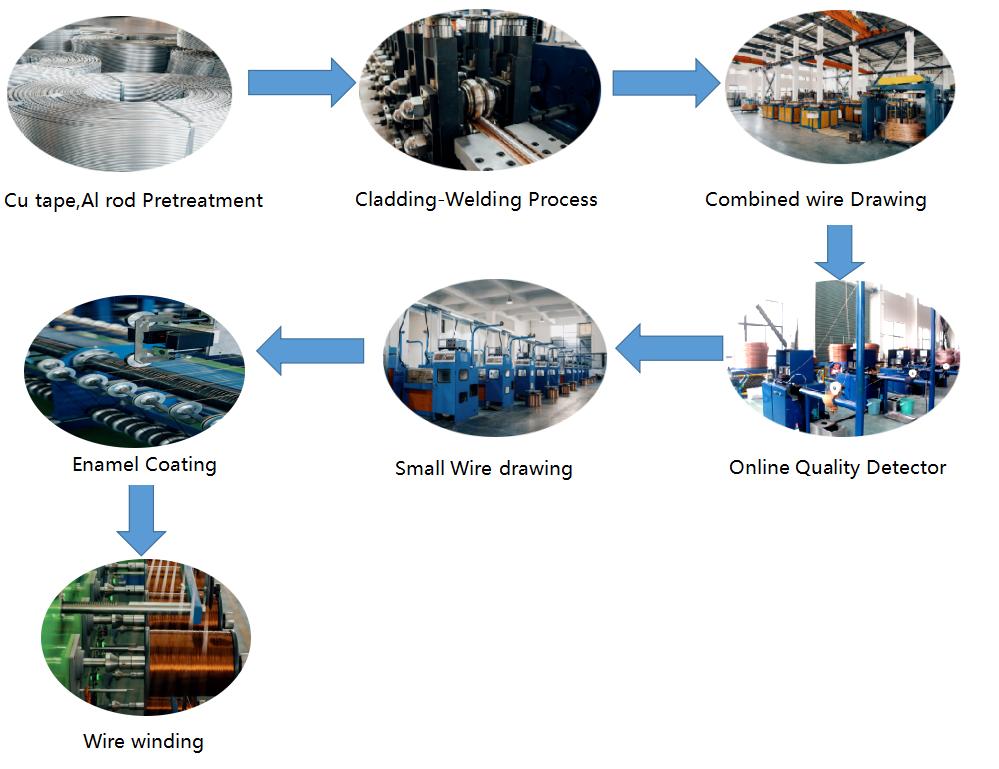

1. DC resistivity

The DC resistivity of CCA wire is approximately 1.45 times that of copper wire; with the same resistance, CCA wire is about 1/2 heavy of copper wire.

2. Good solderability

CCA wire is clad with a layer of concentric copper, so it has the same solderability as copper wire and doesn’t need special treatment as aluminum wire;

3. Light weight

The density of CCA wire is 1/3 of copper wire of the same diameter; very effective to reduce the weight of cables and coils.

| Product Type | General Description | Characteristics |

| PEW/130 | 130Grade Polyester | Good heat resistance and mechanical strength. |

1.Loudspeaker voice coil. Its frequency can reach 500Hz-1600Hz, It can reduce vibration weight and keep high fidelity effect.

2.Monitor deflection coil. It can lower coil temperature, improve image’s stability, increase usage life.

3.Monitor degaussing coil. It can lower product cost.

4.Ordinary motor, medium transformer.

Bobbin Option

| Spool Type | d1 [mm] | d4 [mm] | I1 [mm] | I2 [mm] | d14 [mm] | Spool weight [g] | nom. net wire weight [kg] | recommended for wire sizes [mm] | spools per box | |||||

| Enameled Copper Wire | Enameled Aluminum Wire | Enameled CCA Wire | ||||||||||||

| 10%CCA | 30%CCA | 40%CCA | 50%CCA | |||||||||||

| PT-4 | 124 | 22 | 200 | 170 | 140 | 0.23 | 6 | 2 | 2.5 | 3 | 3.2 | 3.5 | 0.04~0.19 | 4 |

| PT-10 | 160 | 22 | 230 | 200 | 180 | 0.45 | 15 | 4.5 | 5 | 6 | 6.5 | 7.5 | 0.20~0.29 | 2/4 |

| PT-15 | 180 | 22 | 230 | 200 | 200 | 0.54 | 20 | 6.5 | 7 | 8 | 8.5 | 9 | 0.30~0.62 | 1/2 |

| PT-25 | 215 | 32 | 280 | 250 | 230 | 0.75 | 28 | 10 | 11 | 13 | 14 | 15 | 0.65~4.00 | 1 |

| PT-60 | 270 | 32 | 406 | 350 | 300 | 2.05 | 80 | 24 | 24 | 28 | 32 | 35 | 0.65~4.00 | 1 |

Packing